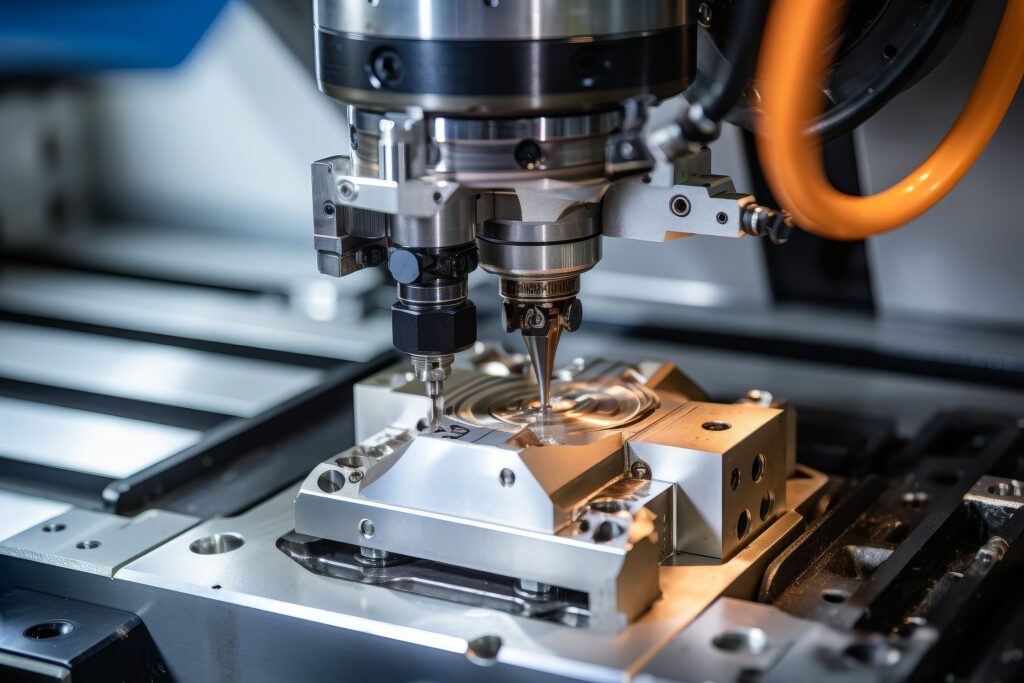

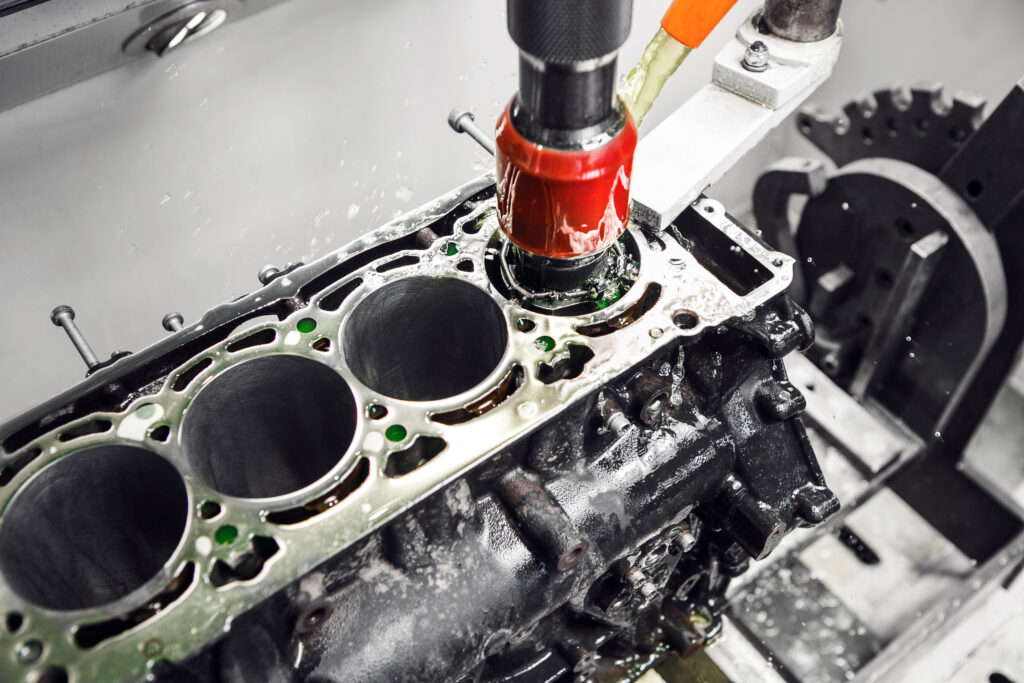

A metalworking fluid (MWF) is a liquid—usually an oil, emulsion, or water-based solution—used during metal machining or shaping processes to provide cooling and lubrication at the tool-workpiece interface

SOLUBLE CUTTING OIL

SPPL MAXKOOL Series are Mineral, semi synthetic & full synthetic based Soluble Cutting Oil that performs extremely well in a wide range of machining operations on both ferrous and non-ferrous metals. MAXKOOL grades are formulated to offer highly stable emulsion, bio-resistant and anti-foam characteristics for use as a general-purpose and heavy duty water-soluble cutting oil/ grinding fluid

PERFORMANCE STANDARDS:PROPRIETARY GRADE

GRADES:

1. MAXKOOL S – SERIES ( Mineral based) Maxkool S-100, S-500

2. MAXKOOL E- SERIES ( Semi synthetic based) Maxkool E-500, E-600,E-700

3. MAXKOOL G- SERIES ( Fully synthetic based) Maxkool G-1000, G-2000

ANTI-RUST OIL

SPPL MAXGARD series of temporary anti-rust oils are formulated from. premium Oils/solvent and internationally proven additive packages. They are tailor made/niche products meeting the most demanding performance criteria. We have Solvent based dewatering type rust preventive oil which leaves thin oily / waxy coating that can be readily cleaned. The other grades are oil based heavy metal free product for cold and hot rolled steel industry

PERFORMANCE STANDARDS:PROPRIETARY GRADE

GRADES:DWS 901, DWS 902, DWS 904, DWS 905, DWS 301, DWS 302, DWS 300,

0-401 CR

STAMPING & PUNCHING OILS

SPPL MAXPUNCH Oils are low viscosity, colorless, low odor, self-evaporating, with synthetic additives specially formulated for stamping, drawing, punching, fine blanking, bending and profiling of fine sheet made of aluminum, steel and non-ferrous metals. It is most suitable for stamping, punching and forming for aluminum fins of air conditioner and radiator industry

PERFORMANCE STANDARDS:PROPRIETARY GRADE

GRADES:SPPL MAXPUNCH 55, MAXPUNCH 75

EDM OILS

SPPL MAXSPARK EDM Oils are specially formulated with premium quality of base oil to give unsurpassed performance. This clear transparent dielectric fluid is odorless and non-toxic. Its low viscosity and high flash point helps to promote a safe and pleasant working environment.

PERFORMANCE STANDARDS:PROPRIETARY GRADE

GRADES:: MAXSPARK EDM Oil V2, V3, V4.

FORMING OILS

SPPL MAXFORM Oils are high-performance neat type forming oils formulated to meet the severe deep-drawing operations like cold heading, back extrusion, bar drawing, deep drawing and arduous cutting operations like fine blanking of sheets, cold forming of tubes, cold forming of valves, very large reductions in seam-welded tubes and high-speed drawing of rectangular sections

PERFORMANCE STANDARDS:PROPRIETARY GRADE

GRADES:SPPL MAXFORM N32, MAXFORM N50, MAXFORM N81 FORMING OILS

CLEANING OILS

SPPL MAXCLEAN series of products are specially formulated to clean or remove oil, dust, dirt, grease, neat type forming oil, cutting oil, drawing oil and anti-rusting oil from components with aluminium, titanium alloy, ferrous and non-ferrous parts. Application method: Dipping and ultrasonic cleaning

NEAT CUTTING OILS

SPPL MAXKUT SERIES Oils are a complete range of neat cutting oils to meet various customer needs, MAXKUT Series Neat Cutting oils are formulated from selected, highly refined, severely hydrotreated base oils and fortified with EP, AW, lubricity additives and designed to cater from the general purpose to severe machining operations of all metals and their alloys

SPPL MAXHONE Oils are very light coloured and low viscosity oils with good lubricity

characteristics for honing operations of all ferrous and non-ferrous metals with good surface

finish.

SPPL MAXQUENCH Series Quenching Oils are high-quality oils that have been designed for the heat treatment of ferrous metals in a range of quenching operations.MAXQUENCH series includes Bright Quenching Oils; Cold Quenching Oils, Hot Oil Quenchants, Tempering Fluids etc. These oils are thermally stable having high flash points & low evaporation losses.

Dive into our range of Petrochemicals , including Lubricants, FDA and Bio Fuels designed to meet industrial needs

Sidhe Petrochemicals Pvt. Ltd. 7th Floor, Tower -A, BPTP Park Centra, Jal Vayu Vihar, Sector -30, Gurugram – 122001, Haryana.